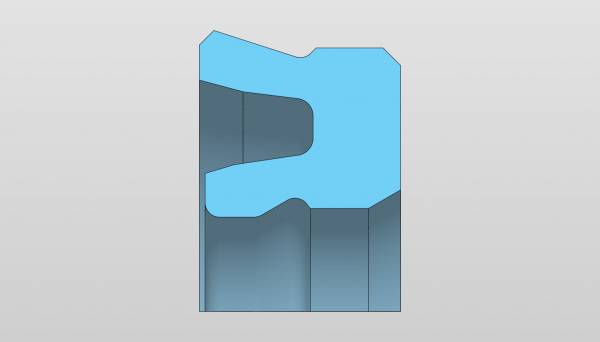

Just like hydraulic systems, pneumatic systems also rely on specially designed seals for optimal performance. Since the working medium in pneumatics—air or other gases—offers poor lubrication, careful seal design is essential. In pneumatic cylinders, seals play a vital role by preventing the escape of compressed air, blocking the entry of contaminants, maintaining the alignment of rods and pistons, and, in some cases, enabling long-term, maintenance-free operation without external lubrication. Unlike hydraulic systems, pneumatic cylinders operate at much lower pressures (up to 16 bar) but demand higher operating speeds (up to 4 m/s), making low-friction sealing critical. Pneumatic seals are used in both rotary and reciprocating applications and include rod seals, piston seals, symmetrical seals, V-rings, wipers, wear rings, static seals, back-up rings, and O-rings. Depending on the application, these seals may be single-acting—sealing in one direction—or double-acting, working in both directions during reciprocating motion. P & H Seals offers a wide range of pneumatic sealing solutions made from high-performance materials such as Polyurethane (PU), Nitrile (NBR), Viton (FKM), Silicone, EPDM, and PTFE, ensuring reliable performance even in demanding environments.

.png)